How to Choose the Right Tpu Film for Your Projects and Applications

As industries continue to innovate, the demand for high-performance materials has surged, with Thermoplastic Polyurethane (TPU) films emerging as a preferred choice across various applications. According to a recent market analysis by Research and Markets, the global TPU film market is projected to reach $2.4 billion by 2025, driven by its versatility and superior properties, including elasticity, durability, and resistance to environmental factors. This growth highlights the significance of selecting the right TPU film tailored to specific project requirements, ensuring optimal performance and longevity.

Dr. Emily Chen, a leading expert in polymer materials and author of "Advancements in Thermoplastic Elastomers," emphasizes the importance of informed choices in this field, stating, "The correct selection of TPU film can significantly impact the performance and lifecycle of the final product." With applications ranging from automotive interiors to medical devices, the nuances of TPU film characteristics must be carefully considered—encompassing factors like thickness, transparency, and mechanical strength. As enterprises aim to leverage these unique properties, understanding how to choose the right TPU film will not only enhance product efficacy but also contribute to sustainable development initiatives in the industry.

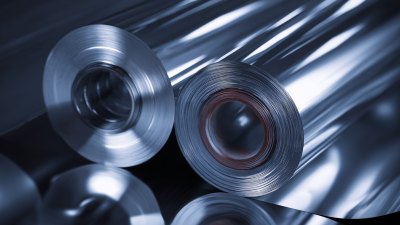

Understanding TPU Film: Composition and Properties in Industrial Applications

Thermoplastic polyurethane (TPU) film is a versatile material widely utilized in various industrial applications due to its unique composition and properties. TPU is a type of elastomer that combines the elastic properties of rubber with the durability and thermal stability of plastics. This duality enables it to resist abrasion, impact, and environmental stress, making it suitable for demanding conditions. The composition generally includes hard and soft segments, which contribute to its flexibility, transparency, and resistance to oil and grease, enhancing its appeal for applications that require both strength and flexibility.

When selecting TPU film for specific projects, it's essential to consider the film's thickness, surface texture, and temperature resistance. Thicker films provide increased durability and are suited for high-impact environments, while thinner options offer greater flexibility. Additionally, surface treatments can enhance adhesion or alter optical properties, making TPU films ideal for use in packaging, automotive, and medical applications. Understanding these properties allows engineers and designers to choose the appropriate TPU film that meets both functional requirements and project specifications effectively.

Key Factors to Consider When Choosing TPU Films for Specific Uses

When selecting the right TPU (Thermoplastic Polyurethane) film for specific projects, several key factors must be considered to ensure optimal performance and satisfaction. Firstly, the mechanical properties of the TPU film are crucial, as they determine its durability, flexibility, and resistance to abrasion. For applications requiring high elasticity and toughness, films with superior tensile strength and elongation at break are essential. This is particularly important in industries like automotive and construction, where films may face harsh conditions and mechanical stress.

Another critical aspect is the chemical resistance of the TPU film. Depending on the environment in which the film will be used, it may be exposed to various chemicals, oils, or solvents. Films designed to be chemically resistant will maintain their integrity and functionality, reducing the risk of failure or degradation during use. Additionally, manufacturers should consider the temperature range of their application, as TPU films can behave differently under varying thermal conditions, affecting their performance and longevity. Understanding these factors will help in choosing the most suitable TPU film that meets the specific requirements of the intended application.

Comparative Analysis of TPU Films vs. Other Polymer Films in Performance

When evaluating the performance of thermoplastic polyurethane (TPU) films against other polymer films, several critical factors come into play, including flexibility, durability, and environmental resistance. TPU films are renowned for their excellent mechanical properties, offering superior abrasion resistance and tensile strength compared to traditional polyethylene or polypropylene films. This makes TPU a preferred choice for applications requiring high elasticity and tear resistance, such as protective covers and automotive components.

Additionally, TPU films exhibit enhanced performance in terms of chemical resistance and weatherability. Unlike some other polymers, TPU maintains its integrity when exposed to oils, solvents, and UV light, making it ideal for outdoor applications and long-term use. Furthermore, TPU films can be engineered for various applications through the adjustment of their hardness and thermal properties, providing versatility that other polymer films may not offer. This adaptability positions TPU films advantageously across various industries, including healthcare, consumer goods, and industrial uses, where performance and reliability are paramount.

Comparison of TPU Films and Other Polymer Films in Performance

This bar chart illustrates the performance comparison of TPU films against other common polymer films. It showcases tensile strength and elongation at break, with TPU films exhibiting superior tensile strength and higher elongation capacity, making them ideal for various applications.

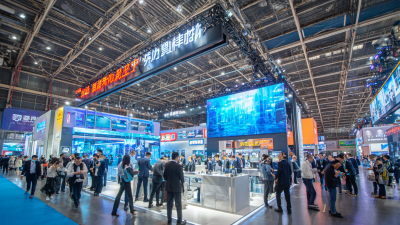

Market Trends: Current Usage Statistics for TPU Films in Various Industries

The use of thermoplastic polyurethane (TPU) films has seen significant growth across various industries, driven by their unique properties such as flexibility, durability, and resistance to abrasions and chemicals. Recent reports from market research firms indicate that the global TPU film market is projected to reach approximately $2.4 billion by 2026, growing at a CAGR of around 6.3% from 2021 to 2026. This growth is largely attributed to increasing demand from key sectors, including automotive, healthcare, and electronics, where TPU films are employed for applications ranging from protective coatings to medical devices.

In the automotive industry, for instance, TPU films are increasingly used for paint protection and interior applications due to their lightweight nature and high-performance characteristics. Data from industry analyses suggest that the automotive segment accounted for more than 30% of the total TPU film market share in 2021. Similarly, in the healthcare sector, the rise of advanced wearables and medical devices is spurring the need for biocompatible and flexible materials, with TPU films being a popular choice thanks to their sterilization compatibility and excellent mechanical properties. As the demand for sustainable and high-performance materials grows, the trend towards TPU films is expected to continue, positioning them as a critical component in various innovative applications.

Case Studies: Successful Applications and Innovations Using TPU Films

Thermoplastic polyurethane (TPU) films have found a range of successful applications across various industries, thanks to their superior properties such as flexibility, durability, and resistance to abrasion. One notable case involves the automotive sector, where TPU films are utilized for protective coatings on vehicle surfaces. These films not only enhance the aesthetic appeal but also provide a barrier against scratches, environmental contaminants, and UV damage. By integrating TPU technology, manufacturers are able to improve the longevity of vehicle exteriors while maintaining a sleek appearance that meets consumer expectations.

In the footwear industry, TPU films have been innovatively applied to enhance both performance and comfort. For instance, high-performance athletic shoes incorporate TPU films in their upper constructions to create lightweight, water-resistant layers that promote breathability and flexibility. This results in footwear that is better equipped to handle the rigors of athletic activity while ensuring comfort for the wearer. The use of TPU films in this context illustrates how innovation can lead to enhanced product performance, offering a competitive edge in a crowded market.

Home

Products

Paint Protection Film

TPU Color PPF

Window Tint

1Ply Primary Film

2Ply Primary Film

2Ply Korean Primary Film

Nano Ceramic Film

Inorganic Nano Ceramic High Insulation Film

Skincare Nano Ceramic Film

5G HD Hot Melt Film

Magnetron Heat Reflection Film

Titanium Nitride Optical Film

Titanium Nitride HD Magnetron Metal Film

Titanium Nitride HD Skincare Film

4mil 99% Safety Film Series

2mil 99% High Insulation King Series

Constant Color High Insulation Film

Constant Color Window Film

Chameleon Window Film

3mil Windshield Film

Headlight Film

Sunroof Film

About Us

Video

News

Blog

Contact Us