How to Choose the Right Tpu Film for Your Project?

When selecting the right TPU film for your project, several factors come into play. The TPU film industry is rapidly growing, with a projected market size of USD 4.2 billion by 2026, according to recent reports. This increase indicates the rising demand for high-performance materials across various sectors. David Hartman, an industry expert, notes, "Choosing the correct TPU film can significantly impact product durability and functionality."

Understanding the specific requirements of your project is crucial. TPU film offers versatility, including excellent elasticity and resistance to abrasion. Yet, many may overlook important details, such as adhesive compatibility or environmental conditions. These overlooked aspects can lead to project failures.

In the quest for the ideal TPU film, one must also account for processing methods and cost-effectiveness. Not all films cater to every application, which underscores the importance of thorough research. Aligning your project's demands with the right TPU film can elevate quality and performance. However, navigating this landscape requires diligence and clarity in decision-making.

Understanding the Basics of TPU Film and Its Applications

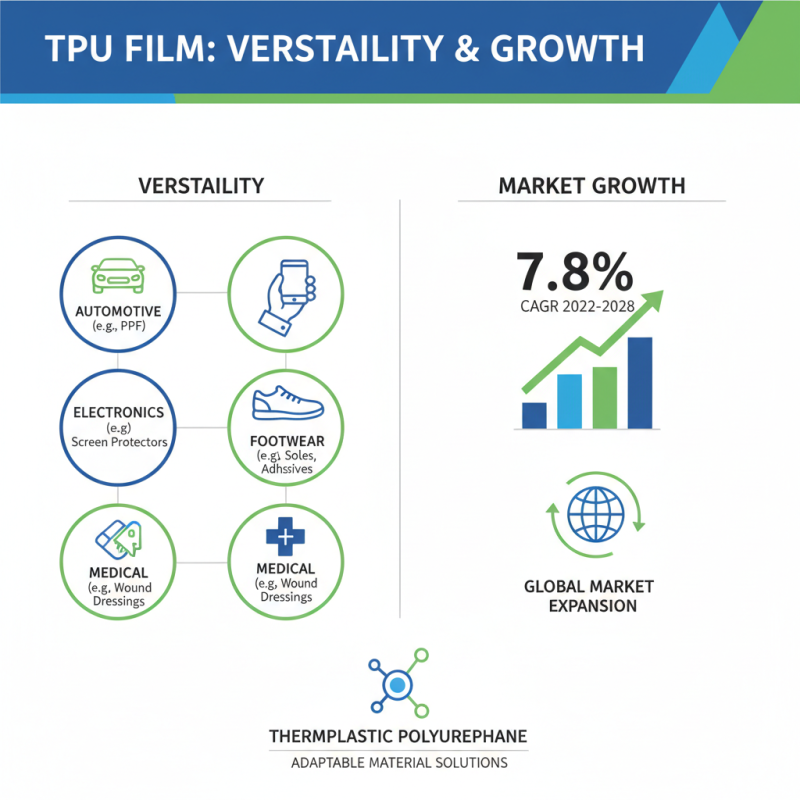

TPU (Thermoplastic Polyurethane) film is a versatile material used in many industries. Understanding its fundamentals can aid in its proper application. According to a recent market report, the global TPU film market is projected to grow at a CAGR of 7.8% from 2022 to 2028. This indicates a rising demand for its products across various sectors.

TPU films have unique characteristics like flexibility, durability, and resistance to abrasion. These attributes make them ideal for applications in automotive, medical, and textile industries. For instance, in the automotive sector, TPU films protect surfaces and enhance aesthetic appeal. In medical fields, their biocompatibility is crucial for creating safe, effective devices. However, choosing the right TPU film can be challenging due to various grades and formulations available.

Some may underestimate the importance of proper selection. A mismatch could lead to performance issues. For example, a film with low tear resistance may not withstand rigorous use in industrial applications. Additionally, environmental factors like temperature and humidity can affect the film's longevity. Recognizing these nuances is essential for optimizing project outcomes.

Key Factors to Consider When Selecting TPU Film for Projects

When selecting TPU film for your project, consider several crucial factors. Start with the thickness of the film. Thinner films offer flexibility, while thicker ones provide durability. Assess your project's needs carefully. Does your application require robustness or lightweight handling?

Next, examine the surface finish. Some films have a matte finish, while others are glossy. Your choice can impact the final look of the product. Color options also matter. Transparent films might be great for visibility. However, colored films can enhance aesthetics.

Testing is vital. Don't hesitate to purchase samples for real-world evaluation. Monitor how the film performs under various conditions. Reflect on your observations. Was the initial choice right? The learning curve can be steep, but it’s essential for success. Choosing TPU film requires understanding your specific needs and allowing room for adjustments.

Thermoplastic Polyurethane (TPU) Film Properties Comparison

Evaluating the Physical Properties of TPU Film

When selecting TPU film for a project, understanding its physical properties is crucial. TPU, or thermoplastic polyurethane, has unique traits that vary between different formulations. Key characteristics to consider include elasticity, hardness, and temperature resistance.

Elasticity affects how the film stretches and returns to its original shape. This quality is vital for applications where flexibility is essential. Hardness is measured on the Shore scale. A higher Shore value means increased durability, but reduced flexibility. For instance, a balance between these properties is often needed. It’s easy to overlook this balance, leading to unsuitable material choices.

Temperature resistance is another important factor. Some TPU films withstand high heat, while others perform better in cold conditions. Selecting the right temperature range can prevent failures during use. One must also consider environmental impacts, as some films may degrade over time. Analyzing these properties helps ensure the TPU film meets project needs effectively. Careful evaluation now can save time and costs later.

How to Choose the Right Tpu Film for Your Project? - Evaluating the Physical Properties of TPU Film

| Property |

Importance |

Typical Values |

Applications |

| Elongation at Break |

Determines flexibility and stretchability |

300% - 800% |

Protective films, wearable applications |

| Tensile Strength |

Indicates durability and resistance to breakage |

20 - 25 MPa |

Industrial applications, automotive seals |

| Hardness |

Affects surface characteristics and wear resistance |

Shore A 60 - 90 |

Footwear, medical devices |

| Coating Adhesion |

Influences the bond strength of additional layers |

> 20 N/cm |

Laminating films, multi-layer applications |

| UV Resistance |

Important for outdoor applications |

> 1000 hours |

Outdoor signage, solar panels |

Appropriate Thickness and Color Options for Your TPU Film Needs

Choosing the right TPU film for your project involves understanding various aspects, particularly thickness and color options. The thickness of TPU film can influence its durability and flexibility. Thicker films may offer extra protection, while thinner ones can provide more ease of handling. Consider the demands of your project and the environment it will face.

When it comes to color, TPU films provide a wide range of options. Transparent films allow for visibility of underlying designs, while vibrant colors can enhance the aesthetic appeal. Keep in mind that some colors may fade faster when exposed to sunlight. Think about the long-term effects of color choice on your project.

Tips: Always request samples of different thicknesses. Test them in real conditions. Observe how they perform. Pay attention to the color stability in your tests. It’s essential to weigh durability against flexibility. Ensure you communicate your project requirements clearly. Reflect on how your choices will impact the final outcome.

Assessing Environmental Impact and Sustainability of TPU Films

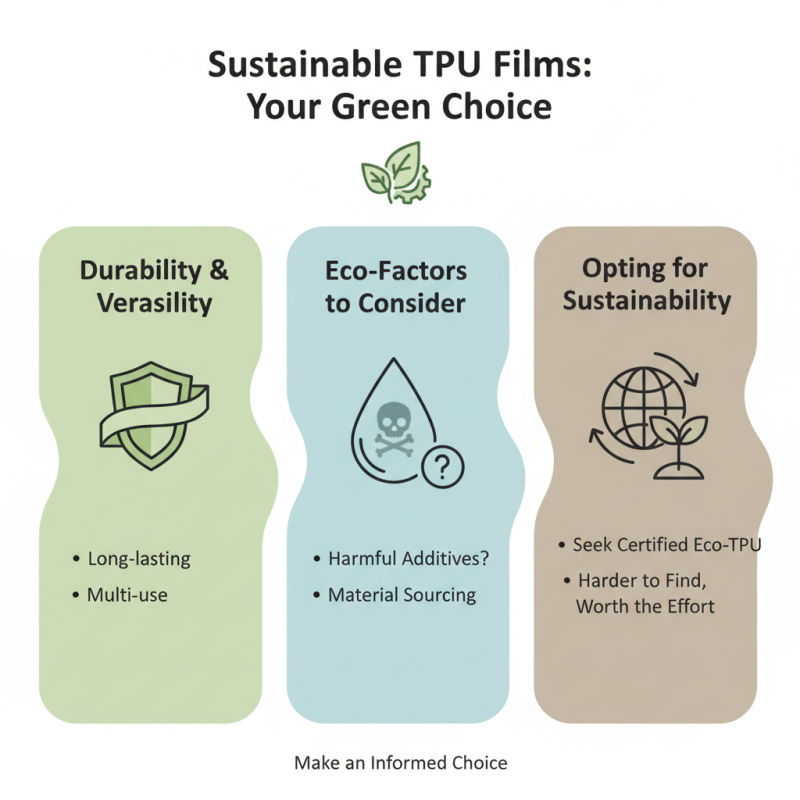

When selecting TPU films for your project, it's crucial to consider their environmental impact. TPU (Thermoplastic Polyurethane) is often lauded for its durability and versatility. However, not all TPU films are created equal. Some may contain additives that can harm the environment. It’s essential to evaluate the sourcing of materials. Sustainable options exist, but they can be harder to find.

The production process of TPU films also affects their sustainability. Traditional methods can emit harmful byproducts. Look for manufacturers using eco-friendly processes. Certifications can help you identify greener choices. Yet, not all claims are transparent. Always dig deeper into the production practices. This may involve more research but leads to informed decisions.

Recycling is another factor to weigh. Some TPU films are recyclable, while others end up in landfills. Understanding the end-of-life impact is vital. Consider how your project aligns with waste reduction goals. Small changes in material choice can lead to significant environmental benefits. Assess, reflect, and aim for a thoughtful approach to your TPU film selection.

Home

Products

Paint Protection Film

TPU Color PPF

Window Tint

1Ply Primary Film

2Ply Primary Film

2Ply Korean Primary Film

Nano Ceramic Film

Inorganic Nano Ceramic High Insulation Film

Skincare Nano Ceramic Film

5G HD Hot Melt Film

Magnetron Heat Reflection Film

Titanium Nitride Optical Film

Titanium Nitride HD Magnetron Metal Film

Titanium Nitride HD Skincare Film

4mil 99% Safety Film Series

2mil 99% High Insulation King Series

Constant Color High Insulation Film

Constant Color Window Film

Chameleon Window Film

3mil Windshield Film

Headlight Film

Sunroof Film

About Us

Video

News

Blog

Contact Us