10 Essential Tips for Choosing the Right TPU Film for Your Projects

Choosing the right Tpu Film for your projects is a crucial step in ensuring optimal results and functionality. As the demand for innovative materials continues to rise, particularly in industries such as automotive, electronics, and sportswear, understanding the key factors that distinguish one Tpu Film from another becomes essential. This guide aims to provide you with ten essential tips that will help you navigate the complexities of selecting the perfect Tpu Film tailored to your specific needs.

In a rapidly evolving market, where the digital landscape is aligning with the latest technological advancements, identifying the right type of Tpu Film can significantly enhance product performance and durability. From the film's chemical resistance to its flexibility, each characteristic plays a pivotal role in the end result. As such, we will delve into the nuances of various Tpu Films available, ensuring that you have the knowledge required to make informed decisions for your projects.

Whether you are a seasoned professional or venturing into the realm of Tpu Film for the first time, this article will guide you through the critical considerations needed when selecting a film that not only meets but exceeds your expectations. Prepare to explore the multifaceted world of Tpu Film and make empowered choices that will drive success in your future endeavors.

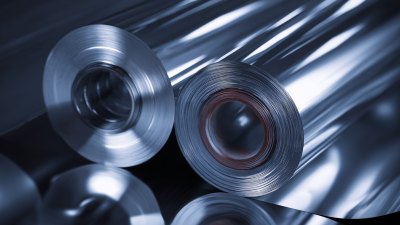

Understanding TPU Film Types and Their Applications

When selecting the right TPU (Thermoplastic Polyurethane) film for your projects, it's crucial to understand the different types available and their respective applications. TPU films are prized for their versatility, durability, and performance in various environments. They come in several formulations, including transparent, colored, and specialty grades designed for specific applications such as automotive, industrial, and consumer goods. Each type possesses unique properties like flexibility, abrasion resistance, and adhesion, making it apt for distinct use cases.

Understanding the application context helps in narrowing down the material choices. For instance, if the end product requires high clarity and UV resistance, clear TPU films would be more suitable. Conversely, if abrasion and chemical exposure are primary concerns, a more robust variant might be necessary. Awareness of these specifics ensures that the selected TPU film not only meets performance requirements but also enhances the longevity and effectiveness of the final product. As global markets for products like screen protectors expand, emphasizing the right TPU film will be imperative for maintaining competitive advantages in innovation and product reliability.

10 Essential Tips for Choosing the Right TPU Film for Your Projects

| Tip No. |

Tip |

Type of TPU Film |

Applications |

| 1 |

Determine the film thickness needed |

Standard TPU Film |

Protective covers, bags |

| 2 |

Assess chemical resistance requirements |

Chemical Resistant TPU Film |

Automotive applications |

| 3 |

Look for UV stability |

UV Stabilized TPU Film |

Outdoor signage |

| 4 |

Evaluate flexibility and softness |

Soft TPU Film |

Textiles, clothing |

| 5 |

Consider the clarity of the film |

Clear TPU Film |

Protective films, displays |

| 6 |

Check for adhesion properties |

Adhesive TPU Film |

Bonding applications |

| 7 |

Analyze the tear resistance |

High Tear Resistant TPU Film |

Industrial applications |

| 8 |

Evaluate the cost-effectiveness |

Budget TPU Film |

General use |

| 9 |

Review environmental impact |

Eco-friendly TPU Film |

Sustainable products |

| 10 |

Seek expert recommendations |

Custom TPU Film |

Tailored applications |

Key Factors to Consider When Selecting TPU Film

When selecting the right TPU (thermoplastic polyurethane) film for your projects, there are key factors to consider to ensure both functionality and sustainability. One critical factor is the film's environmental impact. With a rising demand for sustainable products, recent industry reports indicate that over 60% of consumers are willing to pay more for eco-friendly materials. This shift is pushing companies to focus on biodegradable and recyclable options in their TPU film choices, aligning with a broader industry trend toward sustainable packaging solutions.

Another essential aspect is the film's mechanical properties, which include abrasion resistance, flexibility, and elasticity. Studies have shown that the right TPU film can enhance product durability by up to 30%, which is crucial for applications ranging from automotive parts to consumer electronics. Additionally, the film's clarity and adhesion characteristics impact the overall aesthetic and performance of the final product. Therefore, careful evaluation of these physical properties, alongside sustainability considerations, will help ensure that your project not only meets consumer demands but also upholds environmental responsibility.

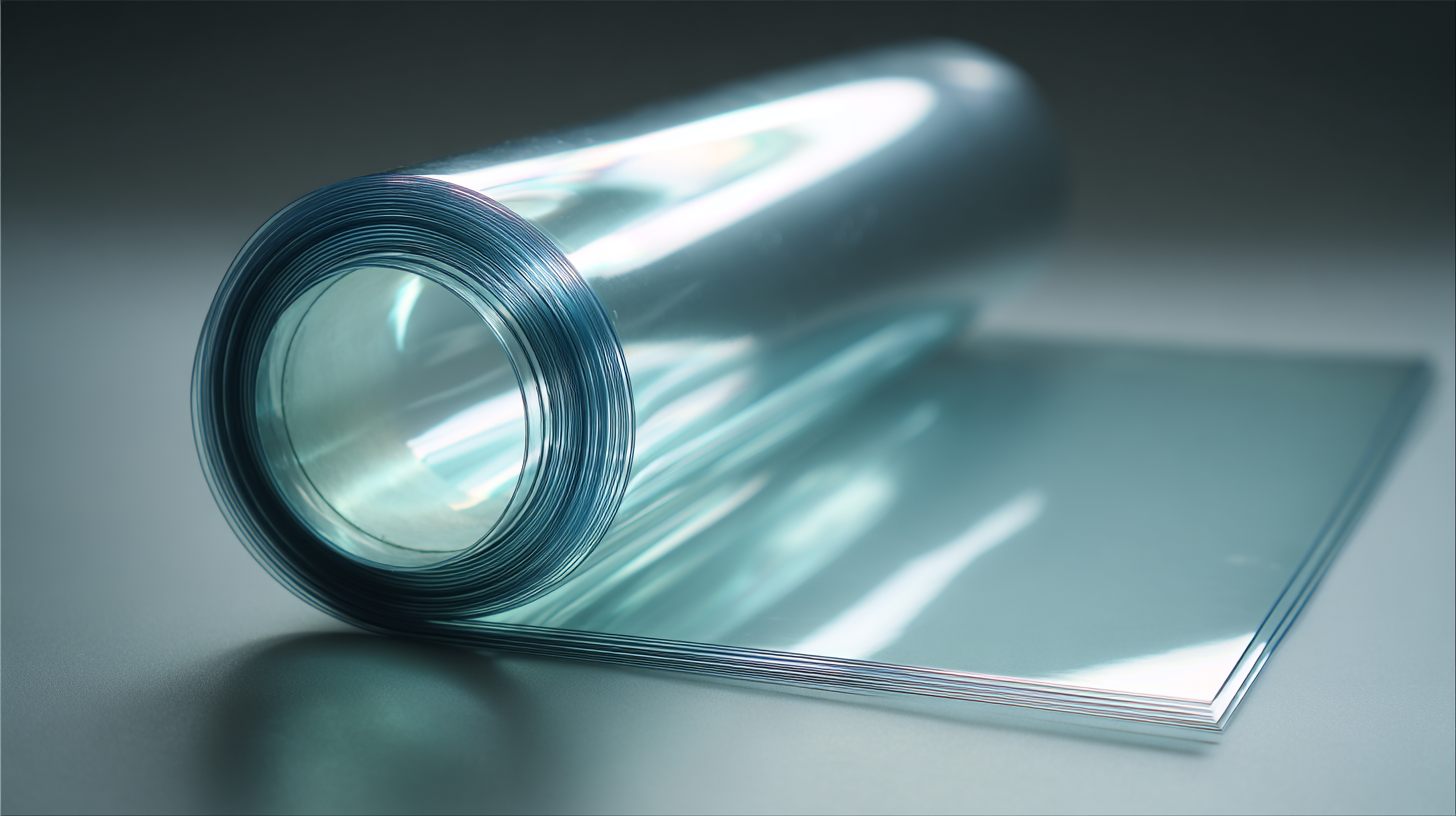

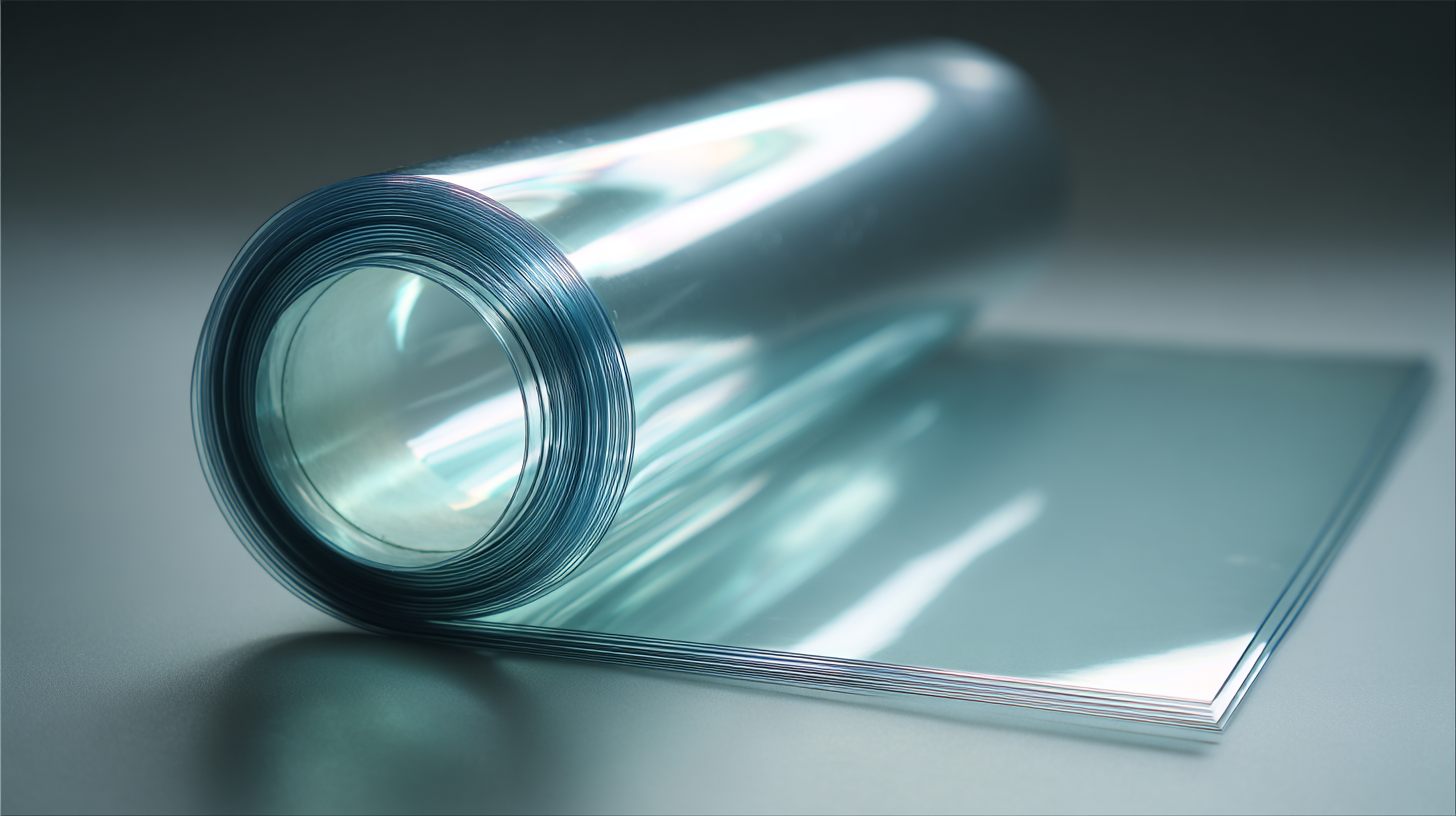

Performance Characteristics of TPU Films for Various Projects

When selecting a TPU (Thermoplastic Polyurethane) film for various projects, understanding its performance characteristics is crucial. TPU films are celebrated for their elastic properties, durability, and resistance to abrasion. According to an industry report by Research and Markets, the global TPU film market is projected to grow at a CAGR of 6.5% between 2022 and 2027, driven by increasing demand in automotive and textile applications. This growth illustrates the film’s versatility, making it ideal for projects that require both flexibility and strength.

When selecting a TPU (Thermoplastic Polyurethane) film for various projects, understanding its performance characteristics is crucial. TPU films are celebrated for their elastic properties, durability, and resistance to abrasion. According to an industry report by Research and Markets, the global TPU film market is projected to grow at a CAGR of 6.5% between 2022 and 2027, driven by increasing demand in automotive and textile applications. This growth illustrates the film’s versatility, making it ideal for projects that require both flexibility and strength.

Different TPU films exhibit varying levels of hardness, transparency, and adhesion, which can significantly affect their performance in specific applications. For instance, a report by Grand View Research highlights that soft-grade TPU films are preferred for applications involving stretchable materials, such as wearable devices, thanks to their superior elongation properties. Meanwhile, harder grades provide excellent resistance to chemicals and environmental degradation, making them suitable for more demanding industrial applications. By aligning the performance characteristics of TPU films with project requirements, designers can maximize functionality and longevity in their products.

Cost-Effectiveness: Balancing Quality and Budget in TPU Film Choices

When considering TPU films for your projects, cost-effectiveness plays a vital role in guiding your choices. The balance between quality and budget is crucial, especially in a market filled with various options. Reports indicate that while high-end TPU films can range significantly in price, mid-range choices often provide a satisfactory blend of durability and affordability. For instance, many users have noted that opting for mid-grade films can yield significant savings without sacrificing protective qualities, making them suitable for projects where budget constraints are paramount.

Further supporting this, industry studies reveal that lower-cost TPU films can still offer robust resistance to scratches and daily wear, akin to their pricier counterparts. For example, a recent analysis of screen protectors showed that well-reviewed mid-tier options effectively shield devices from damage while staying wallet-friendly. Additionally, consumers increasingly prioritize not just the initial cost but also the longevity and performance of the TPU films, reinforcing the importance of making informed decisions to achieve optimal value and protection for their investments.

Future Trends in TPU Film Technology for 2025 and Beyond

As we gaze into the future of TPU (Thermoplastic Polyurethane) film technology, projections suggest a robust growth trajectory driven by advancements in material properties and applications. According to a report by Allied Market Research, the global TPU film market is expected to reach $1.5 billion by 2025, expanding at a CAGR of over 9%. This growth is largely attributed to the increasing demand for high-performance materials in industries such as automotive, aerospace, and healthcare. New formulations are anticipated to enhance the film's flexibility, durability, and resistance to chemicals, further broadening its applicability.

Innovations in TPU film technology are set to focus on eco-friendly manufacturing processes and the integration of smart features. Industry experts predict an increase in biobased TPU films, reflecting a broader trend towards sustainability. Research indicates that the use of renewable resources in TPU production can reduce carbon emissions by up to 30%, aligning with global efforts to combat climate change. Additionally, the integration of smart technology, including sensors and self-healing properties, is expected to revolutionize the usability of TPU films, making them more versatile across various sectors. As we move towards 2025, these trends will likely redefine the possibilities of TPU films and their role in future applications.

Future Trends in TPU Film Technology for 2025 and Beyond

Home

Products

Paint Protection Film

TPU Color PPF

Window Tint

1Ply Primary Film

2Ply Primary Film

2Ply Korean Primary Film

Nano Ceramic Film

Inorganic Nano Ceramic High Insulation Film

Skincare Nano Ceramic Film

5G HD Hot Melt Film

Magnetron Heat Reflection Film

Titanium Nitride Optical Film

Titanium Nitride HD Magnetron Metal Film

Titanium Nitride HD Skincare Film

4mil 99% Safety Film Series

2mil 99% High Insulation King Series

Constant Color High Insulation Film

Constant Color Window Film

Chameleon Window Film

3mil Windshield Film

Headlight Film

Sunroof Film

About Us

Video

News

Blog

Contact Us

When selecting a TPU (Thermoplastic Polyurethane) film for various projects, understanding its performance characteristics is crucial. TPU films are celebrated for their elastic properties, durability, and resistance to abrasion. According to an industry report by Research and Markets, the global TPU film market is projected to grow at a

When selecting a TPU (Thermoplastic Polyurethane) film for various projects, understanding its performance characteristics is crucial. TPU films are celebrated for their elastic properties, durability, and resistance to abrasion. According to an industry report by Research and Markets, the global TPU film market is projected to grow at a