Why Tpu Film is the Best Choice for Your Next Project

In the realm of material selection for various projects, understanding the unique properties and benefits of different options is crucial. Among these, Tpu Film has emerged as a standout choice for designers, engineers, and manufacturers alike. This versatile material is celebrated for its exceptional flexibility, durability, and resistance to environmental factors, making it suitable for a wide array of applications. Whether you're focusing on product packaging, protective coverings, or innovative design elements, Tpu Film offers a blend of functionality and aesthetic appeal that can elevate the quality of your work.

As we delve deeper into the reasons why Tpu Film is the best option for your next project, we will explore its remarkable characteristics that contribute to its growing popularity. From its ability to withstand wear and tear to its adaptability in various climates, Tpu Film stands out in a crowded market of materials. Moreover, its eco-friendly properties and ease of processing further solidify its reputation as an ideal choice. By choosing Tpu Film, you are not just opting for a material; you are choosing a reliable partner in your pursuit of excellence.

Understanding TPU Film: Composition and Properties

Thermoplastic polyurethane (TPU) film is gaining popularity across various industries due to its exceptional properties and versatility. Composed of polyether or polyester-based urethane, TPU film offers a unique combination of flexibility, durability, and resistance to abrasion and tearing. This polymer is synthesized through the reaction of diisocyanates with polyols, resulting in a material that can be tailored to meet specific requirements. Its elastomeric nature allows it to stretch and bend without losing its shape, making it ideal for applications that demand resilience and adaptability.

The properties of TPU film make it particularly well-suited for a variety of projects. Its excellent chemical resistance ensures that it can withstand exposure to oils, solvents, and other harsh substances. Additionally, TPU film boasts impressive thermal stability, functioning effectively in a range of temperatures without compromising its integrity. Moreover, its transparent or translucent appearance allows for aesthetic appeal while maintaining functionality. With its lightweight design and ease of processing, TPU film can be easily fabricated into different forms, enabling designers and engineers to create innovative solutions tailored to their individual project needs.

Advantages of TPU Film in Various Industries

TPU (Thermoplastic Polyurethane) film is increasingly gaining traction across various industries due to its unique properties and versatility. One of the key advantages of TPU film is its exceptional durability. It exhibits high resistance to abrasion, tearing, and impact, making it suitable for applications in the automotive, medical, and construction sectors. In the automotive industry, for instance, TPU film is used for protective coatings that safeguard surfaces from scratches and chemicals, thereby extending the lifespan of components.

In addition to its durability, TPU film is notable for its flexibility and stretchability. This characteristic makes it an ideal choice for industries such as fashion and outdoor gear manufacturing, where comfort and mobility are essential. TPU film can be used in the production of breathable, waterproof garments that maintain their shape while allowing freedom of movement. Furthermore, its recyclable nature aligns with the growing demand for sustainable materials, making it a favorable option for environmentally conscious companies. As industries continue to seek innovative solutions that meet both performance and sustainability standards, TPU film stands out as a superior choice.

Applications of TPU Film in Diverse Projects

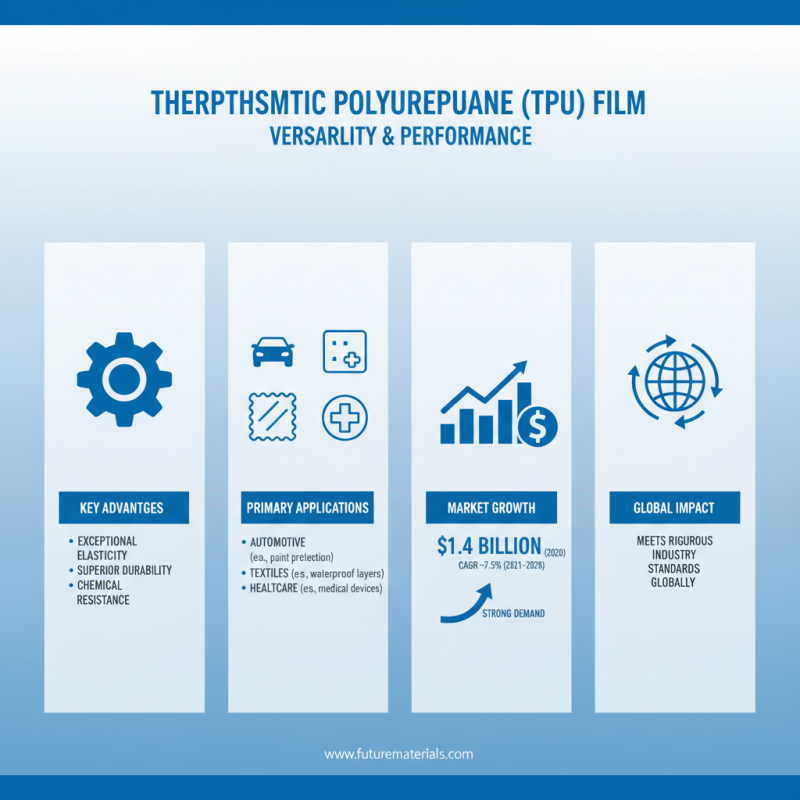

Thermoplastic Polyurethane (TPU) film is increasingly recognized for its versatility and performance in a wide range of applications. In sectors like automotive, textiles, and healthcare, TPU film demonstrates significant advantages due to its exceptional elasticity, durability, and resistance to chemical exposure. The global TPU market was valued at approximately $1.4 billion in 2020 and is projected to grow at a CAGR of around 7.5% from 2021 to 2028, indicating a strong demand across various industries. This growth reflects the material’s ability to meet the rigorous standards required in diverse applications.

In automotive applications, TPU film is often utilized for protective coatings and sealing components, enhancing longevity and resistance to wear. Similarly, in the textile industry, TPU film serves as an excellent laminate material, providing waterproofing and breathability in clothing and outdoor gear. A recent report from Transparency Market Research highlights that the demand for TPU in textiles is expected to significantly contribute to the overall market growth, as consumers increasingly seek high-performance materials. In the healthcare sector, TPU’s biocompatibility makes it an ideal choice for medical devices and equipment, further emphasizing its multifunctional applications and adaptability across varying project needs.

Comparing TPU Film with Other Material Options

When considering materials for your next project, the comparison between TPU (Thermoplastic Polyurethane) film and other options is crucial. TPU film stands out due to its unique balance of flexibility and durability. Unlike traditional plastics, TPU is significantly more elastic, which allows it to withstand wear and tear, making it an excellent choice for products requiring longevity in performance. This flexibility also means it can adapt to different shapes without losing its integrity, which is often a drawback in rigid materials like PVC or standard polyethylene.

One of the main competitors to TPU is PVC, known for its cost-effectiveness. However, PVC lacks the same environmental resilience and strength that TPU offers. Additionally, TPU is less brittle than PVC, making it suitable for applications in various climates without the risk of cracking or breaking. It also maintains clarity better than many alternatives, which is vital for aesthetic applications.

Tips: When selecting a material, consider the specific requirements of your project, such as environmental exposure and durability needs. Always evaluate the long-term benefits of the material over initial costs. For instance, choosing TPU might lead to savings in the lifecycle of the product due to its extended durability.

Factors to Consider When Choosing TPU Film for Your Project

When selecting TPU film for your project, it is essential to consider various factors to ensure you choose the best option. First and foremost is the application of the film. Different projects may require specific thickness, flexibility, and durability levels. Assessing the environmental conditions—such as exposure to UV light, temperature variations, and moisture—is crucial, as TPU films can exhibit varying performance based on these elements.

Another key consideration is the film's adhesion properties. Depending on the surfaces you plan to bond or apply the TPU film, ensuring compatibility is vital for a successful outcome. Additionally, evaluating the film's chemical resistance can significantly affect its longevity and performance in particular applications. Finally, budget constraints and availability might also play a role in your decision-making process. By thoroughly analyzing these factors, you can confidently choose the right TPU film that meets your project's specific requirements.

Home

Products

Paint Protection Film

TPU Color PPF

Window Tint

1Ply Primary Film

2Ply Primary Film

2Ply Korean Primary Film

Nano Ceramic Film

Inorganic Nano Ceramic High Insulation Film

Skincare Nano Ceramic Film

5G HD Hot Melt Film

Magnetron Heat Reflection Film

Titanium Nitride Optical Film

Titanium Nitride HD Magnetron Metal Film

Titanium Nitride HD Skincare Film

4mil 99% Safety Film Series

2mil 99% High Insulation King Series

Constant Color High Insulation Film

Constant Color Window Film

Chameleon Window Film

3mil Windshield Film

Headlight Film

Sunroof Film

About Us

Video

News

Blog

Contact Us